This Is Ingenious

Xerox never stops innovating, reimagining, building, and doing. Xerox is always innovating to produce printers, presses, and technology that gives your business the competitive edge.

Xerox's Ingenious Merger Of Quality And Productivity Gives Your Business Advanced Automation

In the automation of anything, quality and productivity present opposing challenges and for years in the print industry, quality and productivity have presented challenging odds. The customer’s choice between quality or productivity was forced because achieving both was too difficult and too time consuming for a press manufacturer to produce a press that provides both, productivity and quality. That is no longer the case. The iGen® 5 Press brings quality and productivity together, automatically, through advanced automation that unlocks the consistent visual splendor your customers want, with a productivity that increases their margins. There is no trial and error involved and no need for manual operator intervention. The iGen® 5, and the automation it delivers, vanquishes the time consuming processes that other press solutions require. And what is the result? Your customers get extraordinary CMYK with less labor and waste so, their business makes more money.

Xerox's Ingenious Configurable Platform Gives Your Business The Ultimate Investment Protection

The ingenious Xerox innovative press design merges the best characteristics of its industry-leading iGen® Press into a single, optimally configurable iGen® 5 platform. Your print team chooses the speed, ink colors, paper length, and the feeding/finishing which is needed to best accomplish the profitable result. The iGen® 5 platform not only provides a configurability strategy to deliver the exact solution your print team needs, but it also ensures your business continues to benefit from Xerox’s future iGen® 5 innovations. What your business invests into the iGen® 5 platform, with its productivity technology, gives your business a built in level of protection that stems from the ability of the platform to always be ready to perform as it has the ability to stay up to date, and scale, with tomorrow’s demands.

Xerox's Ingenious 5th Print Station Lets Your Business Add Value Beyond CMYK

The ingenious innovation of Xerox’s optional 5th print station unlocks serious flexibility. Your print business, all of a sudden, has the flexibility to extend the color gamut or to add high-value specialty effects, inline. The iGen® 5’s Gamut Extension technology dramatically increases your printing business’ ability to match a wider variety of PANTONE® colors. The choices of Orange, Green, or Blue are now valid options as a supplement to CMYK which allows your team to increase their viability in delivering on-brand content at the will of the customer. It doesn’t stop there. Swapping White, Clear, or Fluorescent Yellow Dry Inks into the 5th station enables designers to amplify jobs with spot decorative effects and to provide new stock and security options. Simply ingenious!

Your Best Business Solution Is The One You Create

Xerox knows the best solutions for your print business are the solutions you figure out for yourself. Creating a digital print solution for your business works best when your business can build from the solid foundation with the highest-quality of building blocks. From start to finish, the Xerox® iGen® 5 Press is designed by the ingenious and the most innovative, forward-thinking technology in the industry. With the Xerox® iGen® 5 Press, your business has the ingenious digital press that is second to none.

Contact Oregon Office Solutions

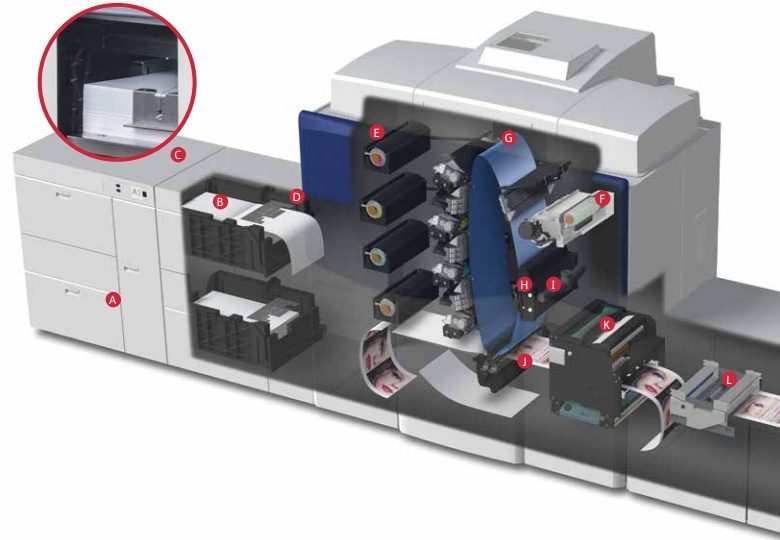

A. Feeder Module: Feeder module (up to six), two paper trays each; load while run; up to 30,000-sheet capacity.

B. Cut-Sheet Format: Large digital cut-sheet format, up to 14.33″ x 26″ (364 mm x 660 mm).

C. Optional Extra-Long Sheet (XLS) Capability: Extra-long digital cut-sheet format, up to 14.33″ x 35″ (364 mm x 889 mm) for additional application flexibility.

D. Gripperless Transport: Gripperless transport mechanism enhances feeding reliability across a broad range of medias.

E. Standard or Matte Dry Ink: Standard Dry Ink is available in CMYK. The Matte Dry Ink option is ideal for photo-rich applications, particularly those running on uncoated or silk stocks. Available for CMYK and Specialty Dry Inks.

F. Optional 5th Print Station: iGen 5 enables you to add Gamut Extension Colors (Orange, Green, and Blue), Xerox® White, Clear, and Fluorescent Yellow Dry Inks as well as MICR to bring differentiating value to digital applications.

G. Auto Carrier Dispense: This method of combining Dry Ink and carrier yields consistent color uniformity from the first print to the last and from job to job. With Auto Carrier Dispense, operators no longer have to stop the machine and change the developer, resulting in greater machine availability and productivity.

H. Auto Density Control: Every press, be it digital or litho, can be susceptible to density variations and streaks. Auto Density Control is patented technology designed to detect streaks in output before they occur and fix them without operator intervention. The system automatically measures the image density for a series of test patches from the top and bottom of the page. If it detects a difference, it digitally compensates for any inconsistencies — ensuring consistent image density across the page.

I. Automated Image-on-Paper Setup: With Automated Image-on-Paper technology, manual setups are replaced with a predictable, automated routine — eliminating costly and time-consuming image registration setups.

J. Single-Point Transfer: Single-point image transfer to paper with speeds up to 9,000 A4 (150 per minute 3-up on 14.33″ x 26″, 75 per minute 2-up on 11″ x 17″) 4/0 impressions per hour.

Acoustic Transfer Assist Option: Sound waves help to embed toner into media, enhancing print quality on rough or textured stocks.

K. Intelligent Fusing: Intelligent fusing adjusts for differences in stock; runs every sheet at rated speed.

L. Inline Spectrophotometer: We built a spectrophotometer into the iGen 5 paper path and integrated it with the Color Maintenance Tool to tell the operator when the press is ready to print superior output. It makes some pretty remarkable things automatic — things such as High Definition Linearization, Advanced Color Profiling, and Spot Color Calibration.

M. Fuser Module: If you choose the optional XLS capability, your iGen Press will be configured with a Fuser Module to the right of the print engine to accommodate the longer sheets.

N. 26″ (660 mm) Stacker: A larger stacker module (up to four) and two wheeled carts per stacker enable productive stacking up to 26″ (660 mm) media. And, Document Finishing Architecture (DFA) compatibility means you can add your choice of automated inline finishing solutions.

O. Top Tray: Top tray for interrupt jobs, proofs, or subset samples programmed during the course of a run. This tray will be replaced by a larger top tray to accommodate sheets up to 35″/889 mm in length if the optional XLS capability is chosen.

P. Dual Mode Sheet Feeder by C. P. Bourg: As a stand-alone device or as part of the Xerox IntegratedPLUS Finishing Solution, the Dual Mode Sheet Feeder provides an efficient means of preparing jobs for finishers, providing automated finisher setup and for sharing a finishing device with multiple printers.

Q. Xerox IntegratedPLUS Finishing: Selected finishing devices can be set up automatically, through JDF instructions, whether or not they are attached to a specific printer. An operator simply loads sheets and covers into the finishing device, scans a bar-coded banner sheet, and presses “start.” No manual finisher setup is required, because time is money.

Xerox® iGen® 5 Press Specifications

DUTY CYCLE

• iGen® 5 150: 4.5 million impressions

• iGen® 5 120: 3.75 million impressions

• iGen® 5 90: 3 million impressions

RECOMMENDED AVERAGE MONTHLY IMPRESSION VOLUME

• iGen® 5 150: Up to 1 million

• iGen® 5 120: Up to 650,000

• iGen® 5 90: Up to 500,000

PRINTING SPEED

iGen® 5 150

(150 8.5″ x 11″/A4 equivalent per minute)

• 2,250 14.33″ x 35″ 4/0 sheets per hour

• 3,000 14.33″ x 26″ 4/0 sheets per hour

• 3,750 12″ x 18″/SRA3 4/0 sheets per hour

• 4,500 11″ x 17″/A3 4/0 sheets per hour

• 8,250 8.5″ x 11″/A4 4/0 sheets per hour

iGen® 5 120

(120 8.5″ x 11″/A4 equivalent per minute)

• 1,800 14.33″ x 35″ 4/0 sheets per hour

• 2,400 14.33″ x 26″ 4/0 sheets per hour

• 3,000 12″ x 18″/SRA3 4/0 sheets per hour

• 3,000 11″ x 17″/A3 4/0 sheets per hour

• 6,600 8.5″ x 11″/A4 4/0 sheets per hour

iGen® 5 90 (CMYK only)

(90 8.5″ x 11″/A4 impressions per minute)

• 1,800 14.33″ x 22.5″ 4/0 sheets per hour

• 2.400 12″ x 18″/SRA3 4/0 sheets per hour

• 2.400 11″ x 17″/A3 4/0 sheets per hour

• 5,400 8.5″ x 11″/A4 4/0 sheets per hour

IMAGE QUALITY

Resolution

• 2400 x 2400 dpi

Line Screens

• 160 lpi, 180 lpi, 210 lpi, 250 lpi,

Stochastic screening (white only)

• Object-Oriented Halftoning

Process Colors

• Cyan, Magenta, Yellow, Black

Optional Xerox® Print Inspect Solution

• Electronic image quality assurance – 100% inspection of every page

5th PRINT STATION OPTIONS

Gamut Extension Colors

• Orange, Green, and Blue Dry Inks

• Match over 93% of the PANTONE® PLUS

Coated Library within 3dE

• Run at rated speed

Xerox® White and Clear Dry Inks

• Optimized for spot applications

• Create specialty effects

Xerox® Fluorescent Yellow Dry Ink

• True fluorescent dry ink to add optic yellow effects and embellishments on top of or adjacent to CMYK

MICR

• Delivers full color MICR (meeting ANSI X9 MICR specifications)

• 5th print station is dedicated to MICR

• Available in select markets

PAPER FORMAT

Standard Sheet Size

• 14.33″ x 26″/364 mm x 660 mm

Minimum 7″ x 7″/178 mm x 178 mm

IMAGE FORMAT

• Default image area is 3 mm less than sheet size

• Operator-adjustable to 1 mm to 6 mm per edge

PAPER WEIGHT (ALL TRAYS)

• Uncoated: 16 lb Bond to 130 lb Cover

(60 gsm to 350 gsm)

• Coated: 60 lb Text to 130 lb Cover

(90 gsm to 350 gsm)

PAPER FLEXIBILITY

• Coated, uncoated, text, cover, recycled, perforated, tabs, labels, synthetics, magnets, and a wide variety of specialty media

• Optional XLS capability for longer media up to 35″/889 mm

• Optional Thick Stock Capability for high caliper media up to 24 pt (610 microns)

• Mixed-stock jobs supported at rated speed

• No drying time

• Optional Acoustic Transfer Assist

TECHNOLOGY FEATURES

Imaging

• ICC Source and Destination and Fast Path Profiling

• Color check for color monitoring

• Single-point transfer printing

• Color Maintenance Tool

• Closed-loop process controls with

Inline Spectrophotometer

• CMYK or CMYK + optional 5th print station for Orange, Green, Blue, White, Clear, and Fluorescent Yellow Dry Inks

• Load dry inks while running

• Automated Image-on-Paper Setup

Paper Handling

• Mixed stocks in a single run (up to 12)

• Straight paper path

• Wide-radius inverter for second-side imaging

• Collated sets

• Wheeled stacker cart

• Load-while-run paper capability and unload

INPUT CAPACITY

• Two trays per Feeder Module

Top Tray:

Maximum sheet size standard

14.33″ x 26″/364 mm x 660 mm (14.33” x 35”/364 mm x 889 mm with optional XLS capability)

Minimum sheet size

10″ x 8.27″/254 mm x 210 mm

Bottom Tray:

Maximum sheet size standard

4.33″ x 20.5″/364 mm x 520.7 mm

Minimum sheet size

7″ x 7″/178 mm x 178 mm

• Up to six feeder modules/12 trays

• Each tray holds 2,500 sheets 80 lb Coated Text/120 gsm

• Up to 30,000-sheet capacity or more

DELIVERY

• Up to four stackers

• Two carts per stacker

• Stacker cart holds 3,000 sheets 80 lb Coated Text/120 gsm

• Stacker top tray

• Collated offset stack delivery

• Up to 12,000-sheet capacity

OPTIONAL

Roll Input

• Tecnau SheetFeeder™ iG provides up to 50,000 additional sheets per roll (based on 8.5″ x 11″/A4; 20 lb Bond/75 gsm)

• Sheets per roll varies based on core size, cut size, and paper type (coated/uncoated, caliper weight, etc.)

Inserter

• One inserter feeder module (same specs as feeder module), two trays

• Enables the addition of specialty sheets to a job after the fusing process (embossed stocks)

Inline Finishing

• 26″ or 35″ Stacker Side Tray

• Booklet Making: C.P. Bourg® Document Finisher

(BDFEx), C.P. Bourg Booklet Maker (BMEx), or Watkiss PowerSquare™ 224

• Output Stacking: Multigraf PST-52 Stacker

• Perfect Binding: C.P. Bourg® BB 3202 Perfect Binder (PUR or EVA)

• Punching Lay Flats: GBC® FusionPunch® II

• Coating: TRESU Pinta Coating System

• Scoring, Cutting, Slitting, and Perforating: Rollem

JetSlit System or Kama DC76 Die Cutter

PRINT SERVERS

• Xerox® EX-P 5 Print Server Powered by Fiery®

• Xerox® FreeFlow® Print Server

DIMENSIONS

Overall press dimensions based on image tower, two feeders, two stackers

• Two feeders, two stackers: 8,889 lb (4,032 kg); one feeder, one stacker: 7,339 lb (3,329 kg)

• 24′ 2″ x 6′ x 8′ (L x W x H)

7.3 m x 1.83 m x 2.44 m (L x W x H)

More Xerox Production Press Options

If the Xerox® iGen® 5 doesn’t fit your business needs, consider these Xerox® production press options:

Xerox® Iridesse™ Production Press

Xerox® Rialto® 900 MP Inkjet Press

Xerox® Baltoro™ HF Inkjet Press

Xerox® Trivor™ 2400 HF Inkjet Press