Ultra HD Resolution Four Color Quality

The Xerox Iridesse production press brilliance is the incredible four color CMYK quality which is possible with Xerox’s three technologies that provide HD resolution, toner formulation and graphic enhancements. These three technologies will empower your print team to publish a full array of digital jobs, from short run and short turn work, and more, without being forced to make concessions.

The Xerox Ultra HD Resolution and Xerox’s new, low gloss small particle toner formulation, combined with xerographic enhancements, clearly improves image quality.

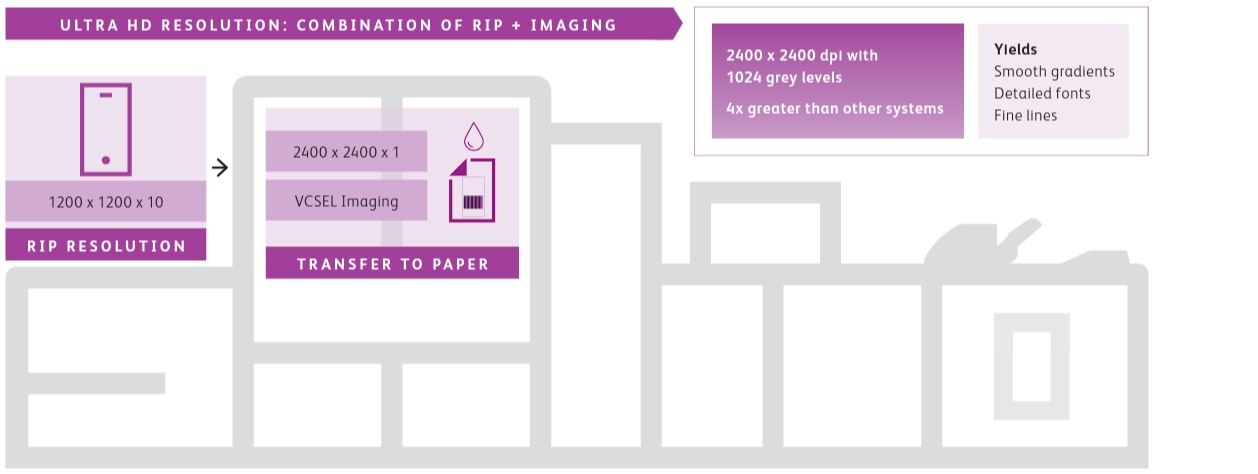

Ultra HD Resolution With Raster Image Processor (RIP) And Imaging

Xerox’s Ultra HD Resolution combines 1200 x 1200 x 10-bit rastor image processor rendering and 2400 x 2400 x 1-bit VCSEL (Vertical-Cavity Surface-Emitting Laser) print imaging, resulting in unmatched, ultra high definition details which produce smooth gradients and beautiful tints, impeccably fine lines, and small text accuracy you won’t find with other presses. Competitor presses may raster image process at the same level, but the image delivery process that feeds data to the Iridesse engine is different in that it delivers 4 times more information, 2400 x 2400 dpi with 1024 grey levels, to the press than other digital presses.

The Stunning Four Color Quality Trick, Smaller Is Better

High quality images in low gloss is a tough trick to pull off and yet the Xerox Iridesse digital production press does just that. The Xerox technology of High Definition Emulsion Aggregate (HDEA) Toner is a defining component of the Iridesse press’s brilliant CMYK quality. Xerox’s HDEA Toner technology reduces the prior toner particle size of 5.8 microns down to a particle size of 4.7 microns. The 4.7 micron particle size creates excellent shadow detail in low gloss, smooth prints. The big bonus is, this high quality, log gloss result is possible even with challenging images.

Consistency Is The Hallmark Of Quality Print Businesses

For print and publishing businesses, consistent quality is the name of the game. You nail that, and you have repeat customers. The Xerox Iridesse production press’s Mark On Belt (MOB) quality check process ensures consistency. Internal process controls guarantee consistency within each print run. Your customers get reliable consistency from job to job. The Iridesse press lays down MOB patches between pages and measures them automatically and continuously during each run while also compensating for any registration or density issues in real time; the process eliminating the potential for color drift, so consistency is reliably delivered, time after time.

Contact Oregon Office Solutions

Submit Web Form Inquiry or Web Form Request

Call (541) 382-0300

More Xerox Production Press Options

If the Xerox® Iridesse™ doesn’t fit your business needs, consider these Xerox® production press options:

Xerox® Rialto® 900 MP Inkjet Press

Xerox® Baltoro™ HF Inkjet Press

Xerox® Trivor™ 2400 HF Inkjet Press